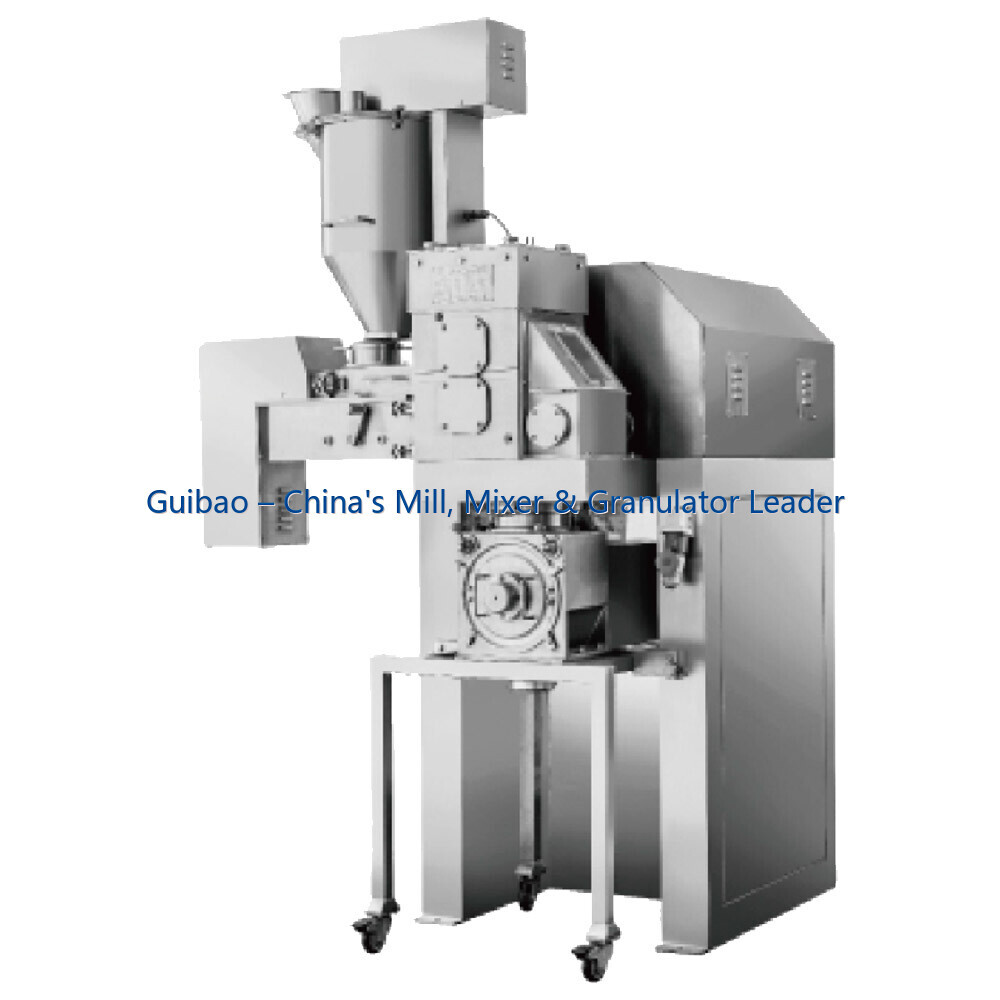

Product Introduction

Main Application

Used in the pharmaceutical, chemical, and food industries to form granules from wet powder materials or to crush dry lumpy materials.

Working Principle

The hexagonal oscillating rotor moves back and forth via mechanical transmission, pushing the material through the sieve screen to form granules or to crush and mill.

Standard Version: Suitable for most general materials.

High-Power Version: Features an upgraded transmission gearbox and motor, ideal for granulating effervescent products and high-density materials.

Heavy-Duty Version (Extract Granulator): Utilizes a reinforced, high-power drive system, specially designed for granulating herb/liquid extract materials.

Customized Oscillating Granulator Design

· Air Sealing: The granulating shaft ends use an air-sealed structure to effectively prevent material ingress into the seal cover.

· Rackless Design: Eliminates sliding friction for extremely high transmission efficiency. Prevents lubrication oil splatter, ensuring a clean and hygienic working environment that complies with GMP requirements.

· No "Black Spots" Contamination: Includes a powder discharge device to expel any powder that might enter the seal, preventing "black spots" and raw material contamination.

· Explosion-Proof (Ex-Proof): All models can be customized with explosion-proof features to meet requirements in hazardous production environments.

· Dust Collection: Can be equipped with a mobile dust collector cabinet and a quick-release dust hood to effectively reduce dust during production.

· Water Cooling: Utilizes tap water or a chiller unit to lower the material temperature during the granulation process.

In addition to the above, the oscillating granulator can be customized for special industry applications, such as for flammable or explosive chemical materials.

Granule size can be adjusted by changing the screen mesh aperture. Choose from stainless steel woven mesh, perforated screen, or nylon mesh based on your specific needs.

Technical Parameters

Get a Free Quote

Advanced technology provides one-stop service for your enterprise

Advanced technology provides one-stop service for your enterprise

24/7 before-sales and after-sales services

24/7 before-sales and after-sales services

Comprehensive technical support

Comprehensive technical support