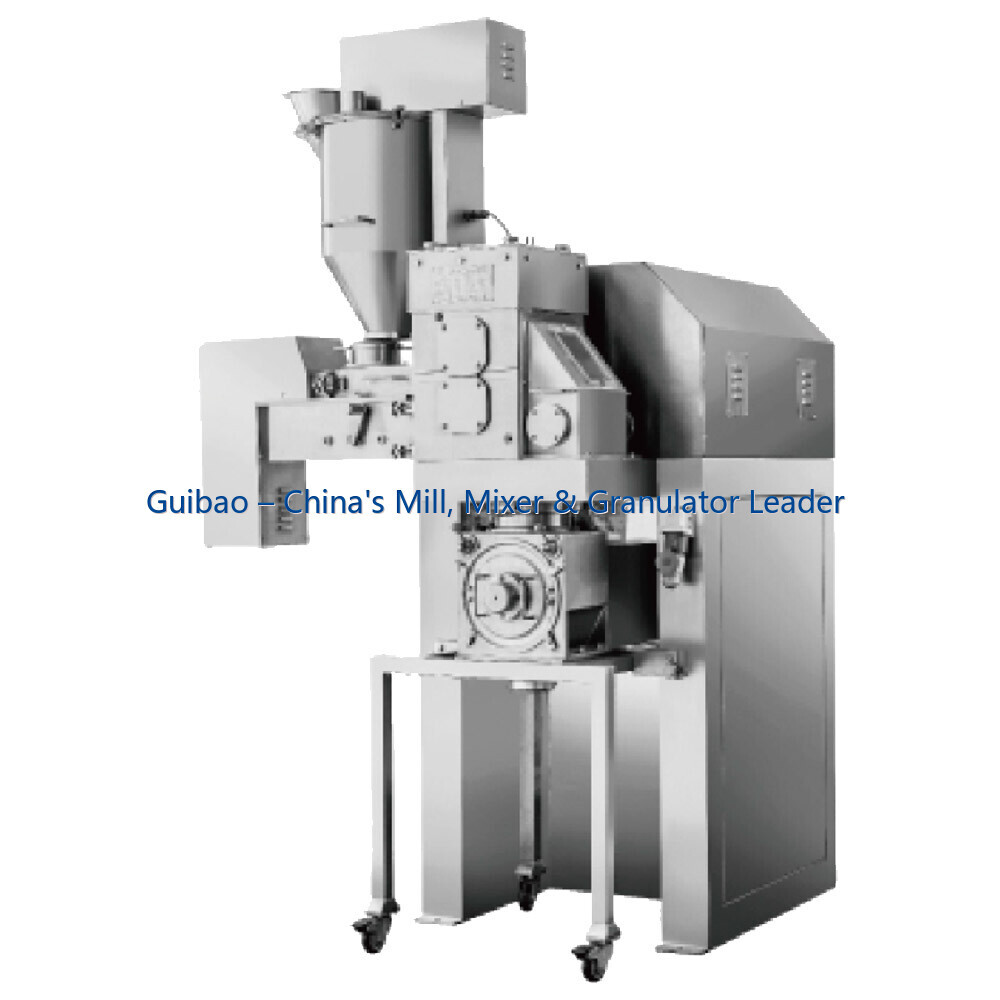

Product Introduction

A cone mill is a device designed to reduce the particle size of materials and ensure uniform particle distribution. It is widely used in industries such as pharmaceuticals, food processing, and chemical engineering.

Working Principle

Materials enter the mill via gravity or vacuum conveying. The rotating impeller pushes the materials outward to the surface of the conical screen. On the screen surface, the materials are sieved and pass through the screen holes. The final product that meets the particle size requirement falls from the grinding chamber and enters the receiver below.

Key Features

·Low Rotational Speed & Low Energy Consumption: Operates at a relatively low rotational speed, which reduces dust generation and heat production—making it suitable for processing heat-sensitive materials. It also minimizes noise and equipment wear.

·Uniform Particle Size Distribution: Ensures a tight particle size distribution of materials, improving the flowability and uniformity of powders, which is beneficial for subsequent processing steps.

·Wide Application Range: Suitable for both wet grinding and dry grinding. It can perform various operations including particle sizing, deagglomeration, sieving, dispersion, and mixing. For instance, in the pharmaceutical industry, it is used for sizing wet granules before drying and dry granules before tableting; in the food industry, it is applied for the deagglomeration of dried fruits.

·Easy Cleaning & Maintenance: Features a simple structure that allows easy disassembly and cleaning, ensuring hygiene standards are met, reducing downtime, and complying with the hygiene requirements of industries such as food and pharmaceuticals.

·High Customization: Can be customized according to different process requirements—different impellers and screens can be selected, and it can also be equipped with gravity or vacuum conveying systems, as well as various drive methods. Some models are further equipped with explosion-proof designs and temperature control modules.

Technical Parameters

Get a Free Quote

Advanced technology provides one-stop service for your enterprise

Advanced technology provides one-stop service for your enterprise

24/7 before-sales and after-sales services

24/7 before-sales and after-sales services

Comprehensive technical support

Comprehensive technical support