Product Introduction

Product Overview

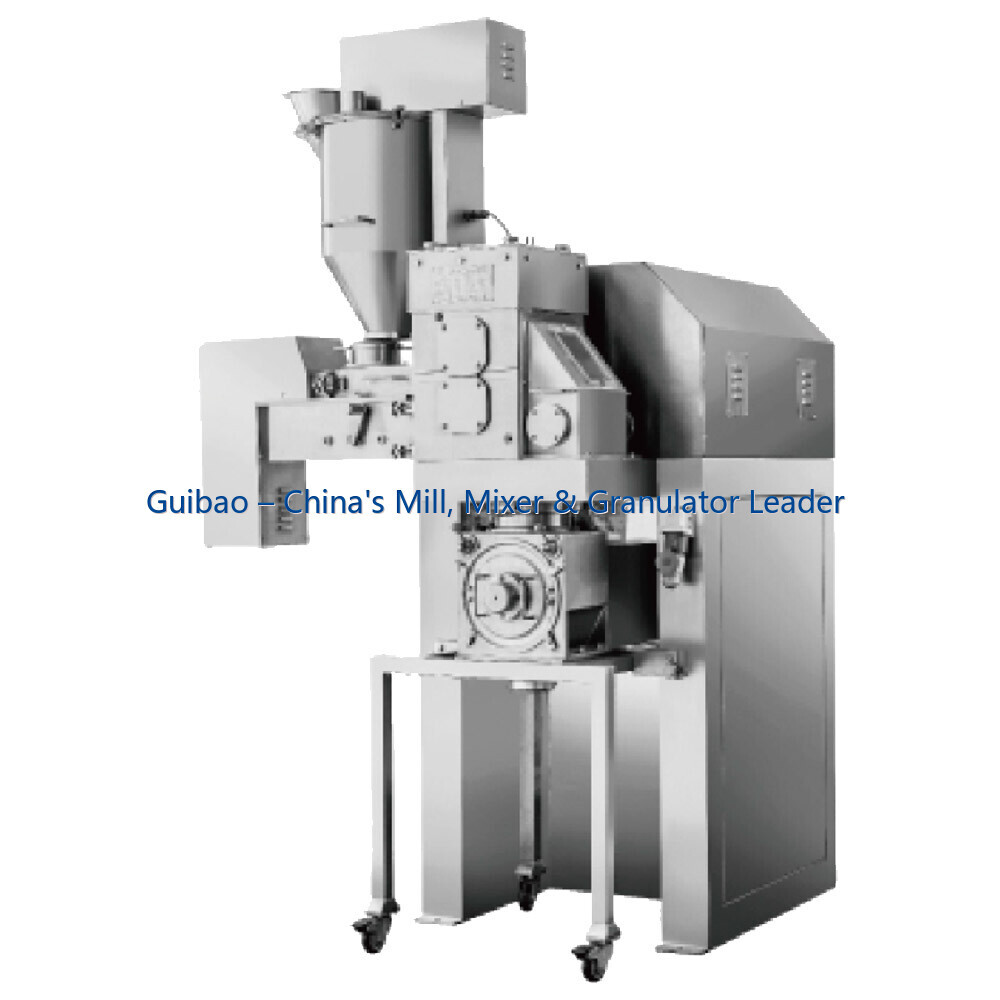

The dry granulator is a kind of equipment that can directly process materials from powder into granules without intermediate processes such as adding water for stirring, mixing into granules, and drying.

The dry granulator has the following characteristics:

1.Direct granulation of dry powder without the need for any binders.

2.The materials are formed by mechanical extrusion, which does not damage the chemical properties of the materials and does not reduce the effective content of the products.

3.The pressure wheels are arranged up and down, eliminating the influence of gravity on the materials and ensuring the uniformity of the materials before tableting.

4.The gap between the pressure wheels is adjustable, making the density of the tablets consistent and the granulation uniform.

5.Low energy consumption and small floor space.

6.High granulation rate and high production efficiency.

7.Equipped with a hydraulic system, and the hardness and density of the granules can be adjusted.

8.The equipment has a simple structure and is easy to disassemble and clean.

9.Equipped with a vacuum pumping device to make the tablets more compact and the granulation rate higher.

10.Three types of patterned pressure wheels, namely the reticulated pattern, straight pattern, and smooth surface, can be matched with materials of different characteristics.

11.The control system is equipped with an internal memory, which can store tens of millions of groups of production data.

12.The equipment is controlled by PLC, with a beautiful and simple human-machine interface, which is convenient to operate and easy to learn.

The LG series dry granulator is a product with leading technical performance, economy, and environmental protection carefully developed by our company. The equipment has a small footprint, is energy-saving and environmentally friendly, and is easy to disassemble and clean. It is an ideal production equipment for large-scale granulation.

The equipment mainly consists of the following parts:

1.Feeding system

2.Deceleration and direction-changing system

3.Screw feeding device

4.Extrusion system

5.Crushing system

6.Double-stage granule shaping system

7.Front cover

8.Frame

9.Inspection door

10.PLC control system

11.Hydraulic system

12.Pneumatic system

13.Water cooling system

Core Advantages of Guibao Dry Granulators

1. High Equipment Output & High First-Pass Granulation Rate

·Qualified granule output = feed volume × granulation rate. Our dry granulators of the same model boast 10% higher output than competitors. We also offer high-output models like LG240 and LG360.

·Screens adopt welded woven mesh, extending service life and enabling easy installation. The first-pass granulation rate is 15% higher than that of punched screens: 60% for 10-40 mesh TCM formula granules and over 75% for 20-80 mesh chemical drugs.

2. Excellent Sealing Performance: Safeguarding Personnel & Drug Safety

Multiple anti-leakage designs fully protect production safety, complying with GMP and FDA requirements:

·The connection between the feed hopper and cylinder is sealed with a foam silicone rubber strip, fixed by 3 bolts with adjustable tightness—no leakage even during vacuum feeder's feeding and back-blowing.

·The sealing ring at the contact of the material conveying device's end cover and screw features a special structure: it fits rotating parts tightly while maintaining flexibility, with a service life 3x longer than ordinary seals.

·The joint of the front cover door and front panel uses a silicone hollow sealing strip (embedded installation). When closed, the strip adheres closely to the ground frame front panel.

·A water-cooled chiller with a built-in negative-pressure water pump is adopted to greatly reduce pressure in the pressure wheel cavity. Meanwhile, the main shaft end for pressure wheel installation is sealed with 3 rings to eliminate water leakage risks.

·Motors for the granule-shaping and feeding systems are custom non-standard models. Rotating parts are directly mounted on the gear motor shaft (no bearings), preventing lubricating oil leakage from radial shaft seal damage.

·The pressure wheel-contacting sealing plate is made of food-grade PEEK. Its wear resistance is over 10x that of PTFE, with no replacement needed for 3 years. A non-sealing material conveying device is also equipped—mechanical control maintains a small gap between front/rear pressure plates and the pressure wheel to avoid wear, ensuring no drug impurities.

3. Simple Structure & Easy Assembly/Disassembly (Host disassembly < 5 mins, assembly < 8 mins)

·Fewer fasteners (bolts, nuts): Only 16 frequently assembled/disassembled fasteners (at least 10 fewer than competitors). Fewer fastener specifications mean fewer wrench types are needed.

·Optimized tensioning devices, pressure plate devices, and baffle structures: Fewer parts for quick installation.

·Structural optimization reduces assembly/disassembly workload. For example, the gap between the granule-shaping knife and screen frame is fixed—no adjustment is needed after installation, shortening preparation time. This avoids issues like knife idling (low granulation rate, blockage) from excessive gaps or screen scratching from too-small gaps.

4. Other Practical Designs

·No baffle at the extrusion wheel's tableting outlet; the transparent front cover allows easy production observation.

·Our vacuum feeder addresses two common issues (bridging of poor-fluidity materials, respirator blockage after 3-4 hours of use) with anti-bridging and anti-clogging devices, enabling true automated production.

·Integrated electrical control system and host: Small footprint, easy installation and debugging.

Technical Parameters

Get a Free Quote

Advanced technology provides one-stop service for your enterprise

Advanced technology provides one-stop service for your enterprise

24/7 before-sales and after-sales services

24/7 before-sales and after-sales services

Comprehensive technical support

Comprehensive technical support